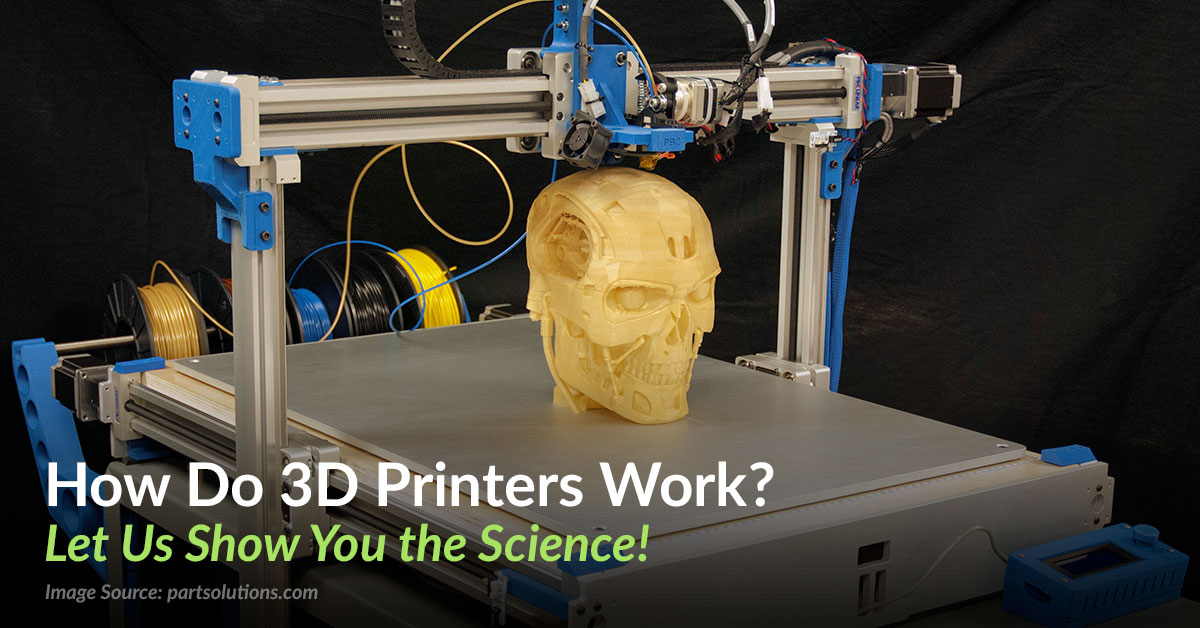

Ultimate Beginners Guide: How Do 3D Printers Work

It’s exciting when you buy your first 3D printer, but some people may take it out of the box and think, “how the heck does this thing work!?”. 3D printers have lot of different moving parts so it’s good to know how the mechanics work so if and when something goes wrong with your prints, you’ll know what to look for!

In our previous blog, “What Is 3D Printing” we go over the different types of 3D printers, printing file formats, and how the process of 3D printing works. Here, I’ll focus on the 5 main components of a 3D printer and how they work.

5 key components of a 3D printer & their function

Picture from 3Dprintingindustry.com

Picture from 3Dprintingindustry.com

1. Print bed: This is the base where all your 3D printed objects are built. The size and dimensions of your print bed is what determines the size of the objects you can 3D print. You can only make something that will fit on your print bed, so you may have to print a larger object in parts if it won’t fit in one piece.

There are two types of print beds: heated and non-heated.

Picture from panucatt.com

Picture from panucatt.com

Heated print bed: If your printer has a heated print bed, it will take a few minutes to heat up before you start printing. Having a heated print bed helps prevent warping of your print. Warping can happen when the filament on your print bed cools at an uneven rate and the material on the edges of your print contract and lift from the print bed. The heat from the bed keeps the temperature of your print more even throughout and can produce a better quality print. If your print starts warping at the top of your print, it’s a sign that your bed is too hot and you should try printing at a lower temperature. Different materials also respond differently to heat. For PLA, the print bed should be heated to a temperature of 50-60 degrees celsius. For ABS material, your print bed should be around 100-110 degrees.

Non-Heated print bed: Non-heated beds can sometimes have trouble with adhesion and warping. Warping with non-heated beds is especially common when using ABS filament or printing a design that takes up a large surface area. To help the filament stick to the bed, use blue tape or Kapton tape and put it on the surface of the print bed evenly. The tape helps secure the initial layers of filament so the model stays in place during the whole printing process. This tape will need to be replaced regularly and each application may only work for one or two prints.

BootsIndustries created a video of what may happen when your filament doesn’t stick to your print bed:

2. Extruder: This is the part that feeds the filament into what’s referred to as the “hot end” – where the filament comes out. Inside every extruder, there is the following:

- a motor to push the filament out

- a nozzle where the filament comes out

- a heating coil to heat up the “hot end” of the extruder

- a temperature sensor that detects when the extruder is at the desired temperature

- a frame to hold everything in

There are two main types of extruders: direct drive and Bowden

Direct Drive Extruder: This extruder’s motor is right above the hot end which moves back and fourth during the 3D printing process. It looks something like this:

Picture from RepRap Wiki

Since the gears and motor are attached to the moving nozzle, it makes the moving part quite heavy and requires a slower printing speed than the bowden. This extruder works well with filament that is flexible because it goes directly into the nozzle with not a lot of room to buckle. It’s also easier to feed filament through this system. Thinner filament (1.7mm filament) also seems to work better than the 3mm filament in this type of extruder. One side effect from the weight of the moving mass is what’s called “ghost lines” where extra lines are created from the moving weight, like in this picture on the left side:

Photo from post on RepRap Forums

Bowden Extruder: A Bowden extruder’s hot end and motor are separate. There is a tube that guides the filament from the motor and gears where it’s fed, to the top of the printer where the hot end extrudes the filament. This makes the weight of the moving part of the extruder much lighter and allows for faster printing.

Most makers with an FDM printer prefer the Bowden extruder because it prints faster and creates a smoother surface. One challenge with the Bowden extruder is that you can run into problems when printing with softer material (like flexible filament). This is because there is a long way for the filament to travel from the gears to the hot end and the filament can buckle or get stuck. It can also be more difficult to feed the filament into the printer.

Picture from RepRap Wiki

3. Hot End: The hot end is where the heated filament comes out and moves across the print bed to create your 3D object! Since this is where the filament heats up & partially liquifies, it get’s quite hot (250 degrees celsius!) and is insulated from the rest of the printer because you wouldn’t want something like this to happen…

Ok, it definitely won’t light you on fire. However, the extruder is hot so be careful not to touch it and burn yourself. Different materials may print best at different temperatures so the sensor is important and it’s temperature can be set with your slicing program.

4. Stepper Motors: There is at least one connected to your extruder to push out filament, and three more that attach to timing belts and pulleys which allow for the extruder to move along the X, Y, and Z axis. Stepper motors divide a full rotation of a motor into equal steps which allows for more precise movement and control. The quality of the motor can make a big difference in the accuracy of a print. This is the same type of motor that is sometimes used to control robots.

5. Filament: While filament isn’t part of a 3D printer, you do need it to print. The two most common types of filament are ABS and PLA which print with most desktop printers. If you want to explore different filaments, there is a lot of new materials like wood and sandstone filament that can give you different looks to your models. Filament comes in spools that attach on the back or side of your printer and feed into the extruder where it heats up and comes out the nozzle. Filament prints in layers and the build up of those layers is what gives you a 3D printed object!

If you want to know more about the different filaments and their properties, check out our article on Popular 3D Printing Filaments and Exotic Filaments to Try Out by 3D Supply Guys!

We’d Love to Hear From You!

Was this article helpful? Was there anything we missed or you’re left confused about. Stay tuned for a follow-up article on how to calibrate your 3D printer once you’ve bought one!